Table of Contents

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

Loved what you read? Share it with others!

MDF vs Plywood: Which One is Right for Your Home Renovation?

Table of Contents

If you're a homeowner, real estate investor, or contractor looking for the right materials for your home renovation or construction project, this blog is for you. Here, you'll learn the key differences between MDF and plywood, their strengths and weaknesses, and how to choose the best fit for your needs. Reading this blog, you'll learn:

- The composition and benefits of MDF and plywood

- The differences in strength, durability, weight, and price when it comes to MDF vs plywood

- Which board is better suited for cabinet and furniture making and interior design, and decor

- The environmental impact of MDF and plywood, including sustainability and recycling

Don't miss out on this comprehensive guide to MDF and plywood. Keep reading to learn more!

Understanding MDF and Plywood

To make an educated choice between MDF and plywood, you need to understand both and compare plywood vs MDF.

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

What Is MDF And How Is It Made?

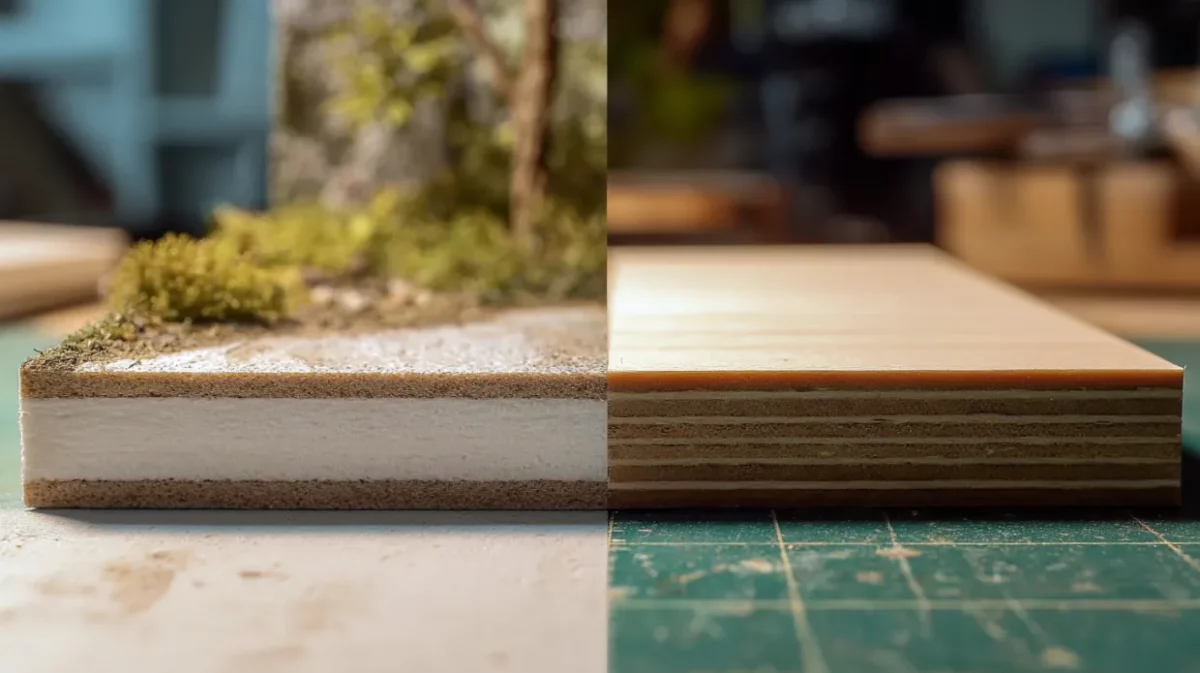

Medium-Density Fiberboard(MDF) is a composite wood product made from recycled wood fibres that are compressed and bonded together with resin under high pressure and heat. The resulting board is dense, smooth, and uniform in thickness, with no visible grain or knots.

What Is Plywood And How Is It Made?

Plywood is a composite wood product made from thin layers of wood veneer that are glued together in a cross-grain pattern. The layers are then pressed and bonded under high pressure and heat, resulting in a strong and durable board with a visible wood grain.

How Does MDF Compare To Plywood In Terms Of Composition?

| Feature | MDF Board | Plywood |

| Composition | Compressed wood fibres and resin | Thin layers of wood veneer glued in a cross-grain pattern |

| Strength | Relatively less strong | High strength and durability |

| Durability | Moderate | More durable due to layered construction |

| Surface | Smooth and uniform | May have natural grain and knots |

| Best Used For | Indoor furniture, decorative elements | Structural uses, cabinets, furniture |

How Does Plywood Compare To MDF In Terms Of Composition?

- While plywood is made from thin layers of wood veneer, MDF is made from compressed wood fibres.

- Plywood is generally stronger and more durable than MDF due to its layered construction.

What Is Plywood And How Is It Made?

Plywood is a composite wood product made from thin layers of wood veneer that are glued together in a cross-grain pattern. The layers are then pressed and bonded under high pressure and heat, resulting in a strong and durable board with a visible wood grain.

What Are The Benefits Of Using MDF vs Plywood?

| Benefits | MDF |

| Cost | Often less expensive than plywood |

| Surface Finish | Smoother, more uniform surface that is easier to paint or finish |

| Sound Insulation | Provides better sound insulation |

| Ease of Workability | Easier to cut and shape compared to plywood |

How Does MDF Perform In Different Settings?

- MDF is commonly used in interior applications, such as furniture, cabinetry, and decorative panelling.

- However, it is not as strong or durable as plywood and may not be suitable for applications that require greater structural integrity.

What Are The Benefits Of Using Plyboard vs MDF?

| Benefits | Plywood |

| Strength & Durability | Greater strength and durability than MDF |

| Structural Applications | Suitable for flooring, roofing, and exterior sheathing |

| Aesthetic Appeal | Visible wood grain adds aesthetic value to projects |

How Does Plywood Perform In Different Settings?

Plywood is a versatile material that can be used in a variety of settings, from interior applications like furniture and cabinetry to exterior applications like roofing and siding. Its strength and durability make it well-suited for structural applications, while its aesthetic appeal makes it a popular choice for decorative projects.

Comparing MDF vs Plywood: Key Difference Between MDF And Plywood

| Feature | MDF (Medium-Density Fiberboard) | Plywood |

| Strength & Durability | Not as strong as plywoodProne to cracking and breaking under stressSmooth and uniform surface | Stronger and more durableResists bending, twisting, and warpingIdeal for load-bearing applications |

| Flexibility | More rigidCan crack if bentCan be curved with heat/moisture, but requires effort | More flexible bends without breakingSuitable for curved designs |

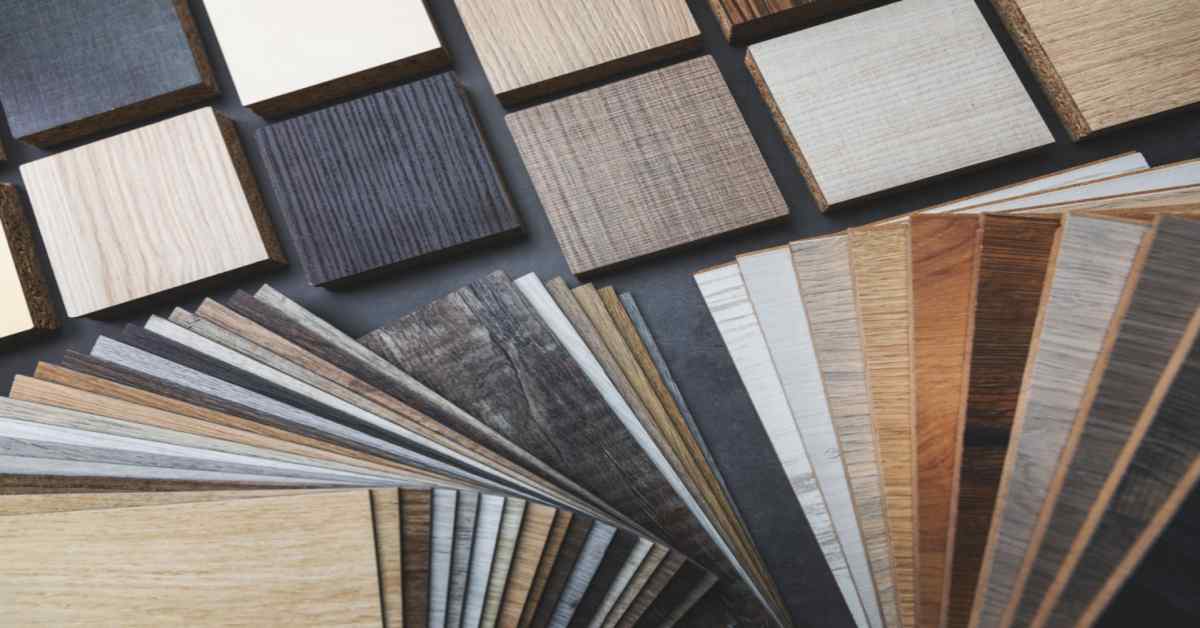

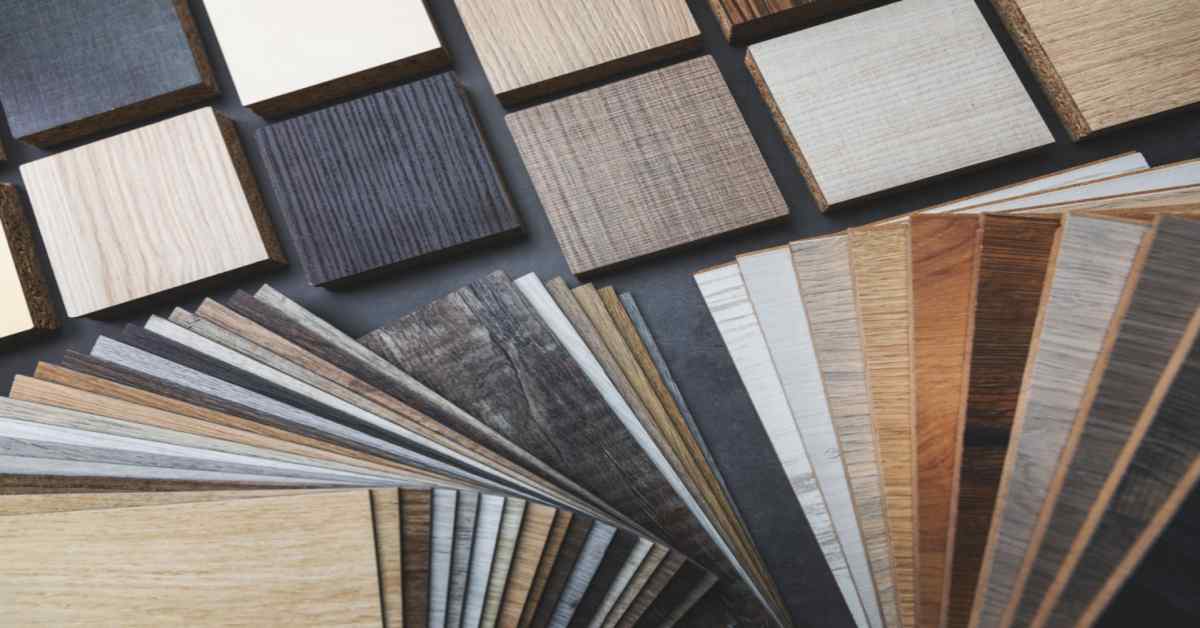

| Variety | Available in various thicknesses, densities, with or without formaldehydeOffered in different finishes like laminates and veneers | Comes in multiple grades and thicknessesAvailable in softwood, hardwood, and marine typesVersatile for different applications |

| Maintenance | Prone to water damageRequires sealing of edgesNeeds to be kept dry | More water-resistant maintenance neededShould be kept clean and dry for longevity |

| Weight | Denser and heavier per sheetBetter sound insulationEasier to cut and shape | Lighter compared to Requires sharper tools for cutting Easier to handle for large projects |

| Price | Generally less expensivePrice varies by brand, quality, and thickness | More expensive than MDF. Cost depends on type and grade |

Ply vs MDF: Which Board Is Better Suited For High-Traffic Areas?

| Feature | MDF (Medium-Density Fiberboard) | Plywood |

| Density | Denser than plywood | Less dense than MDF |

| Scratch & Dent Resistance | More resistant to scratches and dents | Moderate resistance |

| Strength | Weaker compared to plywood | Stronger due to cross-layered construction |

| Impact Resistance | Lower impact resistance | High impact resistance |

| Suitability for High-Traffic Areas | Can be used, but may not hold up under heavy wear | Highly suitable for high-traffic areas due to durability |

| Overall Recommendation | Moderate – suitable for low to moderate use | Better choice for high-traffic and heavy-use areas |

Choosing Between MDF Board vs Plywood: The Right Board for Your Project

| Factors | MDF Board | Plywood |

| Strength & Durability | Less strong and durable. | More durable and stronger. |

| Flexibility | More likely to stay rigid and crack if bent. | Easier to bend and mould to the desired shape. |

| Weight | Denser than plywood, so it tends to be heavier. | Lighter in comparison. |

| Price | Usually less expensive. | More expensive. |

| Maintenance Required | Tends to absorb moisture and swell. Therefore, it requires more care. | Water-resistant and can last long without excess maintenance. |

Choosing the right board can be a crucial decision, and it's important to weigh the pros and cons of MDF vs plywood cabinets carefully. For applications requiring greater strength and durability, plywood is generally the better choice, while MDF is a better option for projects that require smoother surfaces and ease of use. Additionally, factors such as price, weight, and intended use should also be considered.

MDF tends to be less expensive than plywood, but it may not be as strong or durable. On the other hand, plywood can be heavier than MDF, which can be a consideration for larger projects. For applications such as cabinets, plywood may be the better choice due to its strength and durability, while MDF may be a better option for furniture and decorative applications due to its smoother surface. Ultimately, the right board for your project will depend on a variety of factors, and it's important to do your research and choose wisely.

Environmental Impact of MDF and Plywood

Sustainability

In terms of sustainability, both MDF and plywood have their advantages and disadvantages.

Plywood Sustainability:

- Made from natural wood veneer, which can be sustainably sourced.

- Manufacturing can involve toxic adhesives and generate wood waste.

- It may contribute to deforestation if not sourced responsibly.

MDF Sustainability:

- Made from recycled wood fibres, reducing wood waste.

- Often uses formaldehyde-based adhesives, which can be harmful to health and the environment.

- Emits volatile organic compounds (VOCs) during and after production.

Key Consideration:

- The sustainability of both MDF and plywood largely depends on the brand and manufacturing practices.

- Opt for eco-certified products (e.g., FSC-certified) to ensure environmentally responsible sourcing and production.

Recycling and Disposal

Both materials can be recycled, but the process is challenging due to the presence of synthetic resins and other chemicals.

Recycling

- Both MDF and Plywood can technically be recycled, but the process is complex due to the synthetic resins and adhesives used in their production.

- Plywood can often be recycled into particleboard or used in secondary products.

- MDF is less recyclable but can be used as industrial fuel in energy production.

- Their composite structure makes mechanical recycling more difficult and less efficient.

Disposal

- Burning MDF or Plywood is not recommended as it releases toxic fumes (formaldehyde and other VOCs).

- Best disposal practices include:

- Taking them to a certified recycling facility.

- If recycling is not available, dispose of them in a regulated landfill.

- Some local governments may have specific disposal rules, so it’s crucial to check with local authorities before disposal.

This compares MDF (Medium-Density Fiberboard) and plywood to help you choose the right material for home renovation. MDF is smoother, cheaper, and ideal for decorative indoor use, while plywood is stronger, more durable, and better for structural and high-traffic applications. Plywood offers flexibility and moisture resistance, whereas MDF is denser and easier to cut. Environmentally, MDF uses recycled wood but emits VOCs, while plywood may contribute to deforestation if not responsibly sourced. Choosing between them depends on factors like strength, cost, aesthetics, and sustainability.

How Can Nobroker Help?

In conclusion, both MDF and plywood have their advantages and disadvantages. MDF is a cost-effective and versatile material that is best suited for indoor use, while plywood is more durable and weather-resistant, making it suitable for outdoor projects. By understanding the differences between these two materials and their various applications, homeowners, real estate investors, and contractors can make informed decisions about their home renovation projects.

Whether you're renovating a single room or your entire home, NoBroker offers end-to-end solutions with zero brokerage and complete transparency. Book a free consultation today to get started! Explore NoBroker Interior Design Services for hassle-free renovations! Contact us for more information and book a consultation now to take the first step towards your dream home renovation.

FAQ's

A1: MDF is more flammable than plywood, and when it does catch fire, it releases harmful gases. Plywood is a bit more fire-resistant and can withstand heat and flames better than MDF. However, neither material is completely fireproof, so it is best to take precautions and use fire-retardant coatings or treatments when using MDF or plywood in high-risk areas.

A2: While both MDF and plywood can be used outdoors, neither material is ideal for extended exposure to the elements. MDF is particularly vulnerable to moisture, and plywood can warp and delaminate when exposed to water for long periods. For outdoor use, it is recommended to use specially treated plywood or marine-grade plywood that is resistant to moisture, or opt for alternative materials such as fibre cement board or engineered wood.

A3: Yes, both MDF and plywood can be painted. However, due to the porous nature of MDF, it is recommended to prime the surface before painting to ensure even coverage and adhesion. Plywood can also benefit from a primer before painting, especially if it has a rough or uneven surface. It is important to choose the right type of paint for the material and the intended use, and to follow proper application techniques for best results.

A4: While MDF can be painted, it is not recommended for staining as it does not have a natural wood grain and can absorb stain unevenly. Plywood, on the other hand, can be stained and finished to achieve a natural wood look. However, it is important to choose a high-quality plywood with a smooth surface for best results, and to prepare the surface properly before staining to ensure even penetration and colour.

A5: The choice between MDF and plywood depends on several factors such as the intended use, budget, aesthetic preferences, and environmental considerations. MDF is often preferred for indoor use, such as cabinets and furniture, due to its smooth surface and versatility, while plywood is more suitable for structural applications such as roofing and flooring due to its strength and durability. It is important to consult with a professional contractor or designer to determine the best material for your specific project needs.

Recommended Reading

10 Best Apps for Buying Used Furniture in 2026

January 31, 2025

13090+ views

MDF vs Plywood: Which One is Right for Your Home Renovation?

March 13, 2023

4267+ views

10 Smart Home Furniture Ideas That You Must Know!

December 8, 2023

4202+ views

Transform Your Home with Acacia Wood for House Furniture

July 19, 2023

3041+ views

Loved what you read? Share it with others!

Most Viewed Articles

10 Best Apps for Buying Used Furniture in 2026

January 31, 2025

13090+ views

Best 10 Plywood Brands in India: Price, Quality & Durability in 2026

August 3, 2025

9447+ views

Best 18mm Waterproof Plywood 8x4 Price List: Features & Durability in 2026

August 3, 2025

8517+ views

12mm Waterproof Plywood 8x4 Price List: Top Brands, Factors Affecting Price and Tips

July 31, 2025

7947+ views

New and Trending Track Lighting

September 20, 2022

5003+ views

Recent blogs in

Top 11 Best Wood for Furniture in India 2026: Durable and Stylish Options

December 22, 2025 by Krishnanunni H M

How to Hang Pictures Without Nails: Easy No-Drill & 8 Effective Damage-Free Methods

November 24, 2025 by Siri Hegde K

How to Put Hooks on Curtains Easily: Step-By-Step Hanging Method

November 24, 2025 by Priyanka Saha

Type of Wood for Flooring: Best Options for Homes & Durability Explained

November 24, 2025 by Krishnanunni H M

Full RM + FRM support

Full RM + FRM support

Join the conversation!