Table of Contents

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

Loved what you read? Share it with others!

How Mivan Construction Technology Is Transforming the Art of Building!

Table of Contents

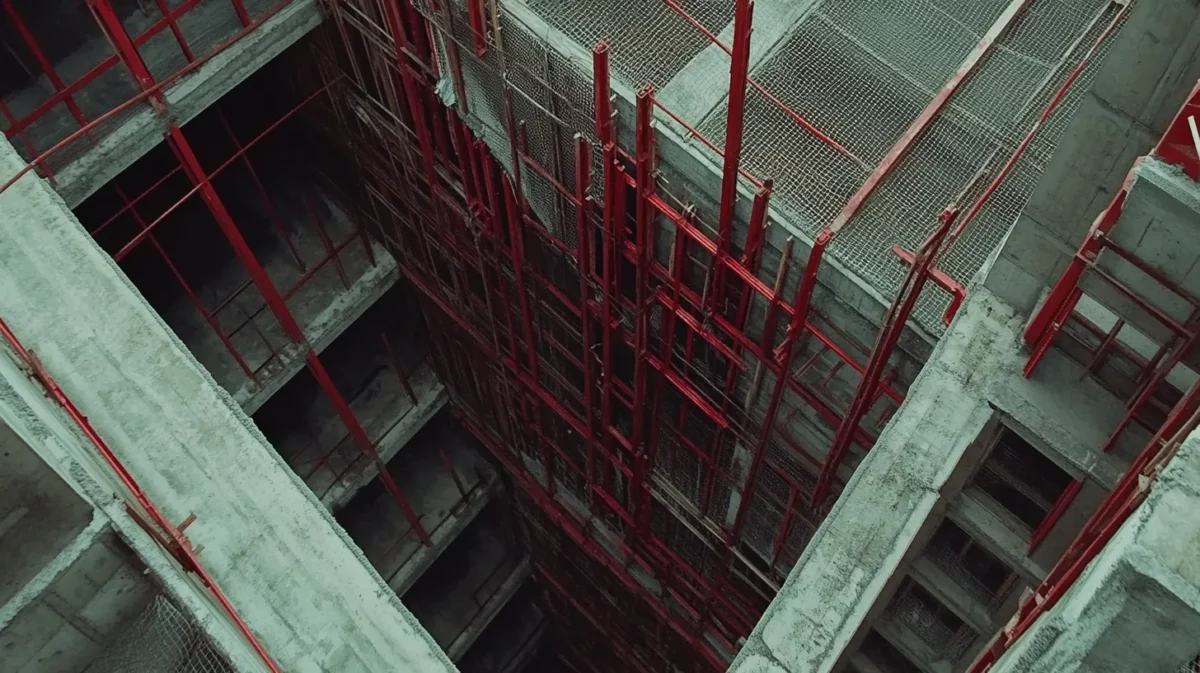

Step into the future of construction with our exploration of Mivan shuttering technology. In a world where delays and workforce shortages challenge traditional methods, Mivan offers a swift and efficient alternative. Casting walls and slabs simultaneously using lightweight aluminium formwork, Mivan outpaces traditional construction, ensuring both speed and durability. Join us as we break down the Mivan vs. brick construction debate, uncover the essence of Mivan formwork, and understand its growing popularity in today's evolving construction landscape.

Mivan shuttering, a rapid construction method using aluminium formworks, enhances building strength and durability. Gaining popularity for mass construction, its demand surged during the pandemic with rising housing needs. Costs vary between Rs. 8000 - Rs. 9000 per sqm, excluding taxes, and can decrease with repeated formwork use. Typically, Mivan slab areas are measured in square meters.

Introduced by the European-based Mivan Company Ltd., the Mivan formwork system revolutionised large-scale housing projects by providing a quick and efficient aluminium structure. Originating in Malaysia in 1990, this method has significantly impacted Indian real estate, particularly in Mumbai, where its cost-effectiveness and quality are highly valued.

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

Mivan technology has been used widely in Europe, Asia, Gulf Countries, and other parts of the globe. It is suitable for constructing a large number of houses in a short period of time using room-size forms to construct walls and slabs in one constant pour on concrete.

What exactly is Mivan Technology?

A European building company created the aluminium formwork technology known as Mivan. In 1990, the Mivan construction business in Malaysia began producing these formwork systems. The Mivan technology has been widely applied throughout the world, including in Europe, the Gulf States, Asia, and other regions.

More than 30,000 square metres of formwork from Mivan Co. Ltd. are currently in use around the globe. In India, the aluminium formwork system is a relatively new invention. It reduces costs, saves time, and raises building quality. L&T used it for the first time in India in 2003 for the construction of both low and high-rise residences and buildings in its projects in Mumbai, Delhi, and South India (Bangalore).

Read: Our Round-Up of the Top 10 Aesthetic Rooms Ideas

Residential buildings and mass housing projects both frequently use the MIVAN system of aluminium shapes. For repeating building patterns and work above the plinth, aluminium formwork is highly economical. The aluminium formwork panels can be made to fit any building condition or component, including distinctive architectural features like bay windows, stairs, and balconies.

This technology is highly remarkable since there is no need for block or brickwork and every component of a structure, including the slabs, beams, walls, columns, staircases, balconies, and specific window hood, is made of concrete. When durability is a major concern, it produces work that is of the highest quality and requires the least amount of upkeep.

Mivan Formwork panels are of exceptional quality and provide consistent dimensions. A high-quality concrete finish is generated with precise tolerances and verticality once the formwork mould is removed. There is no need for additional plastering because of the great tolerance of the finish.

Construction with columns and beams is dropped. Pre-engineered aluminium forms that are precisely constructed, lightweight, and easy to handle are used to cast walls and slabs simultaneously. assembling and erecting the shuttering part, and cementing the slabs and walls together.

Using room-size forms to build walls and slabs in one continuous pour on concrete, Mivan technology is perfect for building a large number of dwellings in a short amount of time while guaranteeing a High-Quality Column.

Cast-in-situ concrete walls and floor slabs that are cast monolithically supply the structural structure in this technique of formwork construction to enable quick construction. Compounds that are heated to cure or cure under hot air can remove forms more quickly. On-site forms for the walls and floor slabs are built to the size of large rooms. These accurate, durable, and manageable shapes are tough and sturdy. They enable several repetitions (around 250).

Concrete is made in RMC batching facilities under stringent quality control, and transit mixers are used to transport it to the site. Before pouring the concrete, the windows, doors, and service duct frames are installed in the form.

The structure also incorporates pre-fabricated items like chajjas, jails, façade panels, staircase flights, etc. When compared to other contemporary construction methods, this demonstrates to be a significant advantage. The system was carefully built and made of aluminium.

The formwork system's modular design makes it simple to fix and remove the forms, and the construction may move along quickly with very little variation in dimensional tolerances. The system is extremely adaptable and is simple to modify for any changes in the layout.

Uses of Mivan Technology in India

Mivan technology has not been used widely in India but is very popular in Gulf countries, Europe, and some parts of Asia. Its use is being preferred in India to complete the most challenging government scheme – Housing for All by 2022.

Major Components of Mivan Formwork

Mivan Formwork components are divided into 4 types based on the location of use: -

1. For Wall Components

- Wall Panel, d) Rocker, c) Kickers, and d) Stub Pin

2. Beam Components

- Beam Side Panel, b) Prop Head and panel for Soffit Beam

3. Deck Components

- Deck Panels, b) Deck Prop and Prop Length, c) Soffit Length

4. Other Components

The other elements used to exclude the wall, beam, and deck parts are internal and external soffit corners, exterior and interior edges for wall panels.

[widget_interior_form]Mivan Construction Versus Conventional Formwork

| Parameter | Mivan system | Regular formwork |

| Speed of development | 7 days/floor | Minimum 21 days/floor |

| Quality of surface finish | Excellent | Putting is required |

| Pre-planning of formwork system | Required | Not required |

| Type of construction | Cast-in-situ cellular construction | Simple RCC |

| Wastage | Very little | Comparatively higher |

| Accuracy in construction | Accurate | Accuracy lesser than modern systems |

| Coordination between offices | Essential | Not required |

| Seismic resistance | Good resistance | Comparatively lesser |

| Dismantling floor piece frames without expelling props | Possible | Impossible |

Advantages and Disadvantages of Mivan Shuttering

Advantages:

- Mivan Formwork requires relatively less labour

- Faster completion of floors

- Lesser number of joints and reduced leakages

- Smooth finishing of wall and slab

- Low maintenance

- More seismic resistance

- Huge carpet area

- Good quality construction work

- Faster completion

- No need for plastering

Disadvantages of Mivan construction system

- High initial cost: The equipment and formwork required for Mivan construction can be expensive, leading to higher initial costs for projects.

- Limited design flexibility: The system is based on pre-fabricated Mivan shuttering components, which can limit the design options available for a project.

- Limited to certain types of buildings: The Mivan system is primarily used for high-rise buildings and large-scale projects, and may not be suitable for smaller or more complex structures.

- Dependence on skilled labour: Proper installation of the Mivan system requires skilled labour, which can be difficult to find and can increase labour costs.

- Limited to certain regions: The Mivan system is not widely used outside of India and Southeast Asia, which can make it difficult to find contractors with experience in using the system.

- Initial setup takes time.

- Leakage issues like seepage, leakages during monsoon.

Area of Use of Mivan Construction Technology

Mivan technology is preferred for constructing a large number of houses in a limited period of time without any trouble. This technology also makes use of room-size structures to construct slabs and walls. It permits shuttering for both slabs and columns in construction. Walls of huge room size, as well as floor slabs, are done right through this kind of Mivan shuttering. They are extremely sturdy and strong forms and are constructed with the utmost accuracy plus it is easy to manage.

The Key Uses of Mivan Shuttering

- Easy to operate within less time

- Includes the 3S scheme of construction to give strength, safety, and speed.

- Slabs and walls are easily formed in one consistent development.

- Assembling and fitting the part of shuttering.

- Beam construction and column are removed.

- Construction of slabs and walls in a simultaneous way.

The Main Features of Mivan Formwork

The major features of Mivan Formwork are given below:

- Load Carrying Capacity

- Striking Time

- Durability

- Cycle Time

Construction Techniques of Mivan Formwork

There are three unique construction techniques:

This is used to give structure to the building and hold the concrete until they gain 50% of the required strength. The aluminium formwork is set around the factory-made steel mesh which is instantly built on the construction site.

Placement of Aluminium Formwork

Along with the wall strengthening steel, room-sized walls and structured floor slabs are built. The aluminium metal slabs are very easy to handle and are also very accurately made. The pin and spearhead system is used to combine these structures, these can be instantly destroyed once the concrete structure is ready.

Pouring of Concrete

After the forms are shaped, high-quality concrete is poured into the structure. The cast is later removed to make way for a hard-concrete structure backed by wall-strengthening steel. These aluminium bodies can be reused nearly 250 times, which means minimum wastage from the construction site.

Limitations of Mivan Formwork:

- Even though there are so many advantages of Mivan formwork the limitations can’t be ignored:

- Services after completion become somewhat difficult due to the small breadth of components.

- It requires consistent planning as well as consistent elevations to be cost-effective.

- Due to box-type construction, shrinkage cracks are possible.

- It is set in design once placed, as any change later becomes difficult.

A kind of aluminium formwork, Mivan shuttering has travelled across the globe and proved to be an economical variant to the traditional method of construction which is labour-intensive and time-taking. Mivan construction is economical when it is a large construction. The use of bricks is totally eliminated and all the components, that is beams, walls, slabs, staircases, etc., is made of concrete. Just like modular kitchens have replaced the traditional ones lending greater space efficiency, aesthetic appeal and time-saving, Mivan formwork has helped the real estate sector with easy assembling and quicker construction. So, the decision is yours on how you would like your house to be built, but know this, no matter what you decide, we at NoBrokers can guide you throughout. You can start your home search by clicking the link below, if you need help you can even drop us a comment below.

Frequently Asked Questions?

Ans: A kind of aluminium formwork, Mivan shuttering is an economical and faster way of construction, and it is slowly becoming popular in India.

Ans: Mivan shuttering is carried out by a skilled workforce that can assemble the aluminium formwork, pour concrete and remove the formwork all at the right time so that the construction is durable.

Ans: Formwork is the process of building a temporary mould. At a later stage, concrete is placed into it and the structure is formed. Traditional formwork is fabricated using timber, but it can also be constructed from aluminium, steel and other materials.

Ans: The Mivan system offers several advantages, including faster construction times, less labour required, improved safety, and higher-quality finished products. It also allows for the creation of complex architectural designs and the use of a variety of finishes on the exterior and interior of the building.

Ans: The Mivan system is suitable for a wide range of structures, including residential buildings, commercial buildings, hotels, hospitals, schools, and more.

Recommended Reading

GFRG Panels: A New Technology in Building Construction

January 31, 2025

261920+ views

How Mivan Construction Technology Is Transforming the Art of Building!

January 31, 2025

178520+ views

Loved what you read? Share it with others!

Most Viewed Articles

GFRG Panels: A New Technology in Building Construction

January 31, 2025

261920+ views

Top Cleanest Cities in India: Swachh Survekshan Top Ranked List

July 25, 2025

221115+ views

Auspicious Dates and Good Nakshatras for Land and Property Registration in 2026

May 21, 2025

200269+ views

How Mivan Construction Technology Is Transforming the Art of Building!

January 31, 2025

178520+ views

CIDCO Lottery 2025: Apply for Affordable Homes in Navi Mumbai

April 30, 2025

135847+ views

Recent blogs in

Indira Awas Yojana 2026: Meaning, Application, Documentation and Benefits in India

January 19, 2026 by Kruthi

Unique Homes Around the World: 5 Extraordinary Houses You Must See in 2026

January 19, 2026 by NoBroker.com

Top Residential Projects In Bangalore: Luxury , Affordable & Upcoming Launches in 2026

January 17, 2026 by Kruthi

Full RM + FRM support

Full RM + FRM support

Join the conversation!