Table of Contents

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

Loved what you read? Share it with others!

Types of Electrical Cables Explained | Complete Guide 2026

Table of Contents

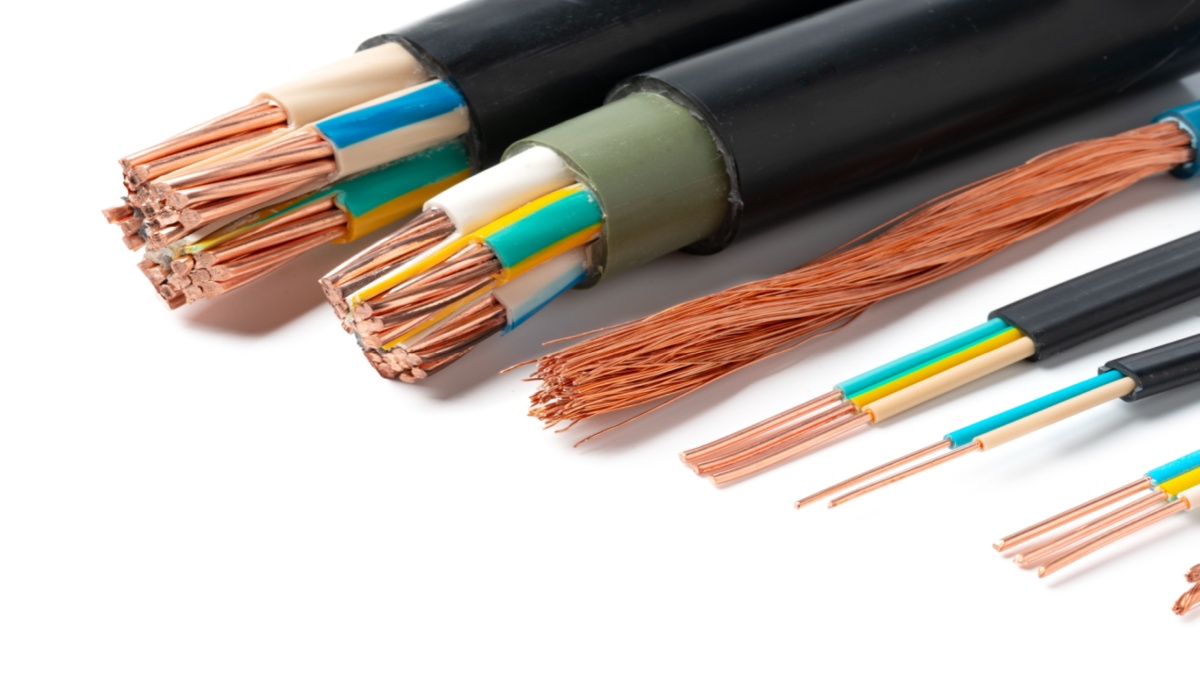

Electrical cables are essential components for transmitting power and data in various applications, ranging from residential wiring to industrial systems. There are various types of electrical cables, each designed for specific uses. Choosing the correct cable type depends on factors like voltage requirements, environmental conditions, and intended usage. Understanding these distinctions ensures optimal performance, safety, and longevity of electrical systems.

High-quality materials, proper insulation, and adherence to safety codes reduce the risks of electrical failures, fires, and energy loss. Investing in suitable cables protects both equipment and individuals, making it a cornerstone of responsible electrical design and installation. Read this blog to learn about the top 20 different types of electrical cables.

Different Types of Electrical Cables

Electrical cables are vital for powering homes, businesses, and industries, providing efficient and safe energy transmission. These cables come in various types, each designed for specific applications, ensuring optimal performance and safety. Below are 20 types of electricity cables:

Quality Service Guarantee Or Painting Free

Get a rental agreement with doorstep delivery

Find the BEST deals and get unbelievable DISCOUNTS directly from builders!

5-Star rated painters, premium paints and services at the BEST PRICES!

1. Coaxial Cable

Coaxial cable wiring is a primary medium for transmitting high-frequency electrical signals. It comprises a central conductor, an insulating layer, and an outer plastic sheath. Due to its superior signal integrity and reduced electromagnetic interference, coaxial cable fittings are widely used in telecommunication and broadcast applications.

| Category | Details |

| Material | Copper, Aluminum |

| Insulation | Polyethylene, Teflon |

| Types | RG-6, RG-59, RG-11 |

| Purpose | Transmit high-frequency signals |

| Common Uses | Cable TV, Internet, CCTV systems |

| Voltage Rating | Up to 300V |

| Current Capacity | Depending on the design, typically, low |

| Durability | High |

| Standards | IEEE, MIL-C-17 |

| Pros | Low signal loss. Shielded from EMI, High-bandwidth |

| Cons | Rigid and less flexible, it is More expensive than other cables |

2. Fibre Optic Cable

Fibre optic cables are the best electric wire for home that use strands of glass fibres to transmit data as light pulses, offering high-speed and long-distance communication with minimal signal loss. Ideal for internet, telecommunication, and medical applications, they are immune to electromagnetic interference and provide greater bandwidth than traditional metal cables.

| Category | Details |

| Material | Glass fibres, plastic coating |

| Insulation | Kevlar, PVC, Teflon |

| Types | Single-mode, Multi-mode |

| Purpose | Transmit data via light pulses |

| Common Uses | Internet, TV, telecommunication, medical imaging |

| Voltage Rating | N/A (uses light pulses) |

| Current Capacity | N/A (uses light pulses) |

| Durability | High |

| Standards | ITU-T, ANSI/TIA, ISO/IEC |

| Pros | High bandwidth, Long-distance transmission, Immunity to EMI |

| Cons | Expensive to install, Fragile compared to metal cables |

3. Twisted Pair Cable

Twisted pair cables consist of pairs of insulated copper wires twisted together to reduce electromagnetic interference and crosstalk. Commonly used in telephone and Ethernet networks, they provide reliable data transmission at lower costs. Twisted pair cables (shielded or unshielded) are ideal for network connections in homes, ensuring reliable data transmission.

| Category | Details |

| Material | Copper |

| Insulation | Polyethylene, PVC |

| Types | Shielded (STP), Unshielded (UTP) |

| Purpose | Reduce electromagnetic interference |

| Common Uses | Telephone lines, Ethernet networks |

| Voltage Rating | Up to 300V |

| Current Capacity | Depending on the wire gauge, typically low |

| Durability | Moderate |

| Standards | TIA/EIA, IEEE |

| Pros | Cost-effective, Easy to install, Good signal quality |

| Cons | Limited distance, Susceptible to interference (UTP) |

4. USB Cable

USB cables are essential for connecting computers and peripherals like keyboards, mouse, and storage devices, supporting both data transfer and power delivery. They consist of a shielded cable with copper conductors, commonly used for charging devices and transferring data at high speeds.

| Category | Details |

| Material | Copper |

| Insulation | PVC, TPE |

| Types | USB-A, USB-B, USB-C, Micro-USB |

| Purpose | Data transfer and power delivery |

| Common Uses | Computers, smartphones, peripherals |

| Voltage Rating | Up to 20V |

| Current Capacity | Up to 5A |

| Durability | High |

| Standards | USB-IF |

| Pros | Universal compatibility, Fast data transfer, Power Delivery |

| Cons | Can wear out over time, Limited length |

5. HDMI Cable

High-Definition Multimedia Interface (HDMI) electrical cable wires are designed to transmit high-quality audio and video signals between devices. They are essential for connecting modern televisions, monitors, and audio systems, offering superior performance with support for high-definition and ultra-high-definition resolutions.

| Category | Details |

| Material | Copper |

| Insulation | PVC |

| Types | Standard, High-Speed, Premium High-Speed, Ultra High-Speed |

| Purpose | Transmit audio and video signals |

| Common Uses | TVs, monitors, gaming consoles, home theatres |

| Voltage Rating | Low |

| Current Capacity | Low |

| Durability | High |

| Standards | HDMI 1.4, HDMI 2.0, HDMI 2.1 |

| Pros | High-resolution support, Easy connection, Single cable for audio and video |

| Cons | Limited cable length, Fragile connectors |

6. Ribbon Cable

Ribbon cables consist of multiple conductors running parallel to each other in a flat, ribbon-like configuration. This electrical cable wire is commonly used for internal connections in computers and electronic devices, such as connecting hard drives and motherboards. Ribbon cables are valued for their flexibility and ease of installation in tight spaces.

| Category | Details |

| Material | Copper |

| Insulation | PVC |

| Types | Flat ribbon, Twisted flat |

| Purpose | Internal connections in electronic devices |

| Common Uses | Computers, printers, internal device connections |

| Voltage Rating | Up to 300V |

| Current Capacity | Depending on the wire gauge, typically low |

| Durability | Moderate |

| Standards | IEC, UL |

| Pros | Easy to install, Flexible, Suitable for tight spaces |

| Cons | Limited shielding, Susceptible to EMI |

7. Shielded Cable

Shielded cables have an additional layer of conductive material wrapped around the core conductors to protect against electromagnetic interference (EMI). They are used in environments with high interference, such as industrial settings and data centres, to ensure reliable signal transmission. Shielded cables come in various configurations, including foil, braided, and served shield types.

| Category | Details |

| Material | Copper, Aluminium |

| Insulation | PVC, Teflon |

| Types | Foil shield, braided shield, served shield |

| Purpose | Reduce electromagnetic interference |

| Common Uses | Industrial settings, data centres, audio/video equipment |

| Voltage Rating | Varies by type and application |

| Current Capacity | Depends on wire gauge and application |

| Durability | High |

| Standards | IEEE, MIL-STD, UL |

| Pros | Reduced EMI, Improved signal quality, Durable |

| Cons | More expensive and bulkier than unshielded cables |

8. Unshielded Cable

Unshielded cables, as the name suggests, lack the additional shielding layer that protects against electromagnetic interference (EMI). This electrical cable wire are commonly used in low-interference environments, such as residential and office settings, for networking and communication purposes. These cables are cost-effective and easy to install, making them a popular choice for house electrical devices and many standard applications.

| Category | Details |

| Material | Copper |

| Insulation | Polyethylene, PVC |

| Types | Unshielded Twisted Pair (UTP), Multi-conductor |

| Purpose | Data and signal transmission |

| Common Uses | Residential networking, office communications |

| Voltage Rating | Up to 300V |

| Current Capacity | Depending on the wire gauge, typically low |

| Durability | Moderate |

| Standards | TIA/EIA, ISO/IEC |

| Pros | Cost-effective, Easy to install, Flexible |

| Cons | Susceptible to EMI, Limited to low-interference environments |

9. Multi-Conductor Cable

Multi-conductor cables contain multiple insulated conductors within a single outer jacket. They are used to transmit multiple signals or power sources simultaneously in complex electrical systems. Commonly found in control systems, instrumentation, and audio applications, these cables are designed to manage multiple circuits, ensuring reliable performance and organisation. The outer jacket protects against environmental factors, mechanical stress, and electromagnetic interference, making it suitable for various industrial and commercial uses.

| Category | Details |

| Material | Copper, aluminium |

| Insulation | PVC, Teflon |

| Types | Paired, Triad, Quadded |

| Purpose | Carry multiple circuits or signals |

| Common Uses | Audio systems, security systems, control systems |

| Voltage Rating | Varies by application |

| Current Capacity | Depends on wire gauge and application |

| Durability | High |

| Standards | UL, IEC |

| Pros | Organised connections, Reduced clutter, Versatile |

| Cons | Bulkier than single-conductor cables, More expensive |

10. Single-Conductor Cable

Single-conductor cables consist of one conductor, typically made of copper or aluminium, surrounded by insulation. This electrical cable wire is ideal for straightforward electrical power or signal transmission in residential wiring, simple electronic devices, and automotive applications. These cables are easy to install and maintain, offering flexibility and reliability for basic electrical tasks. The insulation protects the conductor from damage, moisture, and environmental hazards, ensuring safe and efficient power delivery.

| Category | Details |

| Material | Copper, aluminium |

| Insulation | PVC, Teflon |

| Types | Solid, Stranded |

| Purpose | Power distribution and simple electrical connections |

| Common Uses | Building wiring, electronic devices, appliances |

| Voltage Rating | Up to 600V |

| Current Capacity | Depends on the wire gauge |

| Durability | High |

| Standards | UL, IEC |

| Pros | Easy to install, Cost-effective, Reliable |

| Cons | Limited to simple applications, Not suitable for complex wiring needs |

11. Armoured Cable

Armoured cables feature a protective metal layer, usually made of steel or aluminium, wrapped around insulated conductors. This armour provides enhanced mechanical protection against physical damage, moisture, and chemical exposure, making these cables suitable for harsh environments. Commonly used in industrial, underground, and outdoor applications, armoured cables ensure durability and reliability in demanding conditions. They are designed to withstand heavy wear and tear, ensuring long-term performance and safety.

| Category | Details |

| Material | Copper, aluminium, steel |

| Insulation | PVC, XLPE |

| Types | Steel Wire Armored (SWA), Aluminum Wire Armored (AWA) |

| Purpose | Protect conductors from mechanical damage |

| Common Uses | Industrial applications, outdoor installations, underground wiring |

| Voltage Rating | Varies by design, often high-voltage |

| Current Capacity | Depends on wire gauge and design |

| Durability | Very high |

| Standards | IEC, BS, UL |

| Pros | Highly durable, Resistant to mechanical damage, Suitable for harsh environments |

| Cons | Bulkier and heavier, More expensive |

12. Submersible Cable

Submersible cables are designed to operate in underwater or wet environments. They are engineered to withstand prolonged exposure to water and other liquids, ensuring reliable performance in submerged conditions. The robust insulation and construction protect against corrosion, abrasion, and environmental stress, making these electrical cable wires essential for aquatic and submersible applications.

| Category | Details |

| Material | Copper, stainless steel |

| Insulation | Rubber, Polyethylene |

| Types | Flat, Round |

| Purpose | Provide power in wet or underwater environments |

| Common Uses | Pumps, marine equipment, submersible motors |

| Voltage Rating | Varies by application |

| Current Capacity | Depends on wire gauge and application |

| Durability | Very high |

| Standards | IEC, UL |

| Pros | Waterproof, Highly durable, and Resistant to harsh environments |

| Cons | More expensive, Can be bulky |

13. Control Cable

Control cables transmit control signals in automation systems, machinery, and equipment. They typically feature multiple conductors, offering flexibility and durability for industrial use. These cables are designed to handle low-voltage applications, ensuring accurate signal transmission and control. The insulation and shielding on this electrical cable wire protect you against electrical interference, mechanical stress, and environmental factors, ensuring reliable operation in various industrial and commercial settings.

| Category | Details |

| Material | Copper |

| Insulation | PVC, XLPE |

| Types | Shielded, Unshielded |

| Purpose | Transmit control signals in automation systems |

| Common Uses | Industrial automation, machinery, robotics |

| Voltage Rating | Varies by application |

| Current Capacity | Depends on wire gauge and design |

| Durability | High |

| Standards | IEC, UL, EN |

| Pros | Flexible, Resistant to environmental factors, Reliable signal transmission |

| Cons | Can be bulky, More expensive than simple signal cables |

14. Instrumentation Cable

Instrumentation cables are specialised for transmitting low-level signals in precision instrumentation and measurement systems. They are designed to minimise interference and maintain signal integrity, ensuring accurate and reliable data transmission. This electrical cable wire is used in sensitive environments like laboratories, process control systems, and industrial automation. The high-quality insulation and shielding protect against electrical noise, mechanical stress, and environmental factors, ensuring optimal performance.

| Category | Details |

| Material | Copper, tinned copper |

| Insulation | PVC, XLPE, Teflon |

| Types | Shielded, Unshielded |

| Purpose | Transmit low-voltage signals for monitoring and control |

| Common Uses | Industrial automation, instrumentation panels, control systems |

| Voltage Rating | Low voltage |

| Current Capacity | Low |

| Durability | High |

| Standards | IEC, BS, UL |

| Pros | Noise-resistant, Reliable signal transmission, Flexible |

| Cons | Higher cost, Can be bulky |

15. Thermocouple Cable

Thermocouple cables connect thermocouples to temperature measurement devices, ensuring accurate temperature readings. They are used in industrial process control, laboratory settings, and various applications requiring precise temperature monitoring. This electrical cable wire is designed to withstand high temperatures, chemical exposure, and environmental stress, ensuring reliable performance in demanding conditions. The insulation and construction protect against electrical interference, mechanical damage, and environmental hazards.

| Category | Details |

| Material | Copper, nickel alloys |

| Insulation | Fiberglass, Teflon, PVC |

| Types | Type J, Type K, Type T, Type E |

| Purpose | Connect thermocouples to measurement devices |

| Common Uses | Industrial processes, laboratories, HVAC systems |

| Voltage Rating | Low voltage |

| Current Capacity | Low |

| Durability | High |

| Standards | ASTM, IEC, ANSI |

| Pros | Accurate temperature readings, Resistance to high temperatures, Durable |

| Cons | More expensive than standard cables, Limited to temperature measurement applications |

16. Power Cable

Power cables transmit electrical power from one location to another and are commonly found in industrial, residential, and commercial settings. They are designed to handle high voltage and current levels, ensuring reliable power distribution and minimal energy loss. The high-quality materials and design protect this electrical cable wire against electrical interference, mechanical stress, and environmental factors, ensuring reliable performance and long-term durability.

| Category | Details |

| Material | Copper, aluminium |

| Insulation | PVC, XLPE, rubber |

| Types | Low voltage, Medium voltage, High voltage |

| Purpose | Transmit electrical power |

| Common Uses | Power distribution, industrial machinery, building wiring |

| Voltage Rating | Varies by type, often high voltage |

| Current Capacity | High |

| Durability | Very high |

| Standards | IEC, NEC, BS, UL |

| Pros | High current capacity, Durable, Efficient power transmission |

| Cons | Bulky and expensive compared to lower-capacity cables |

17. Solar Cable

Solar cables connect solar panels to inverters in photovoltaic systems. They are engineered to withstand outdoor conditions and UV exposure, ensuring efficient and safe energy transmission. These cables are designed to handle high temperatures, environmental stress, and mechanical damage, providing reliable performance in solar power applications. The insulation and construction protect against electrical interference, moisture, and environmental hazards, ensuring long-term durability and safety.

| Category | Details |

| Material | Copper, aluminium |

| Insulation | XLPE, PVC, Teflon |

| Types | Single-core, Multi-core |

| Purpose | Connect PV panels to electrical components |

| Common Uses | Solar power systems, PV installations |

| Voltage Rating | Up to 1.5kV DC |

| Current Capacity | Depends on system design |

| Durability | High, resistant to UV and weather |

| Standards | IEC, TUV, UL |

| Pros | UV resistant, Weatherproof, High efficiency |

| Cons | More expensive, Specialised use |

18. High Voltage Cable

High-voltage cables can transmit high-voltage electricity over long distances. They are used in power transmission networks and feature robust insulation to prevent electrical breakdowns. This electrical cable wire are designed to handle high electrical stress, environmental factors, and mechanical damage, ensuring reliable performance in demanding conditions. The high-quality materials and construction protect against electrical interference, environmental hazards, and mechanical stress, ensuring safe and efficient power transmission.

| Category | Details |

| Material | Copper, aluminium |

| Insulation | XLPE, PVC, EPR |

| Types | Overhead, Underground |

| Purpose | Transmit electricity at high voltages |

| Common Uses | Power distribution networks, industrial applications |

| Voltage Rating | Typically above 35kV |

| Current Capacity | High |

| Durability | Very high |

| Standards | IEC, IEEE, BS, UL |

| Pros | High capacity, Long-distance transmission, Robust design |

| Cons | Expensive installation, Requires specialised handling |

19. Ethernet Cable

Ethernet cables are used to connect devices within a local area network (LAN), enabling communication and data transfer. They come in various categories (Cat5e, Cat6, Cat7, etc.), each supporting different speeds and bandwidths. Typically featuring twisted pairs of insulated copper wires, Ethernet cables help reduce electromagnetic interference, ensuring stable and reliable connections. These cables are essential in both home and office networks, facilitating everything from internet access to file sharing and streaming. Their construction allows for durability and flexibility, making them suitable for various networking environments.

| Category | Details |

| Material | Copper |

| Insulation | PVC, Teflon |

| Types | Cat5e, Cat6, Cat6a, Cat7 |

| Purpose | Wired networking |

| Common Uses | Home networks, office LANs, data centres |

| Voltage Rating | Low voltage |

| Current Capacity | Low |

| Durability | High |

| Standards | IEEE, TIA/EIA |

| Pros | Fast data transfer, Stable connection, Versatile |

| Cons | Limited length, Less flexible than to wireless |

20. Portable Cord

Portable cords are flexible and robust cables designed for temporary power connections. They are used in portable equipment, outdoor events, and construction sites, offering durability and ease of use. These cables feature high-quality insulation and construction to withstand environmental stress, mechanical damage, and electrical interference. The flexibility and strength of portable cords ensure reliable performance in demanding conditions, providing safe and efficient power delivery for temporary applications.

| Category | Details |

| Material | Copper |

| Insulation | Rubber, PVC |

| Types | SJO, SJ, SJT, SJTW, SOOW |

| Purpose | Temporary or mobile electrical connections |

| Common Uses | Power tools, appliances, extension cords |

| Voltage Rating | Up to 600V |

| Current Capacity | Varies by type and gauge |

| Durability | High, resistant to abrasion and environmental factors |

| Standards | UL, CSA, MSHA |

| Pros | Highly flexible, Durable, Suitable for various environments |

| Cons | Can be bulky, More expensive than fixed wiring |

Best Electrical Wire for Homes

When choosing electrical wiring for your home, safety, durability, and efficiency are top priorities. The type of wire you select will depend on the specific application, such as lighting, outlets, or heavy appliances. Below are some of the most commonly used and best electric wires for home:

1. RR Kabel PVC Wire

RR Kabel PVC wire is a high-quality single-core lead sheathed cable with a copper conductor and PVC insulation. Due to its excellent conductivity and durability, it is widely used in residential and commercial applications. This wire ensures safe and efficient power distribution in various settings. Its robust design makes it ideal for wiring in both concealed and open environments, providing long-lasting performance.

Benefits

- Low heat generation, reducing the risk of overheating.

- Lead-free, making it environmentally friendly.

- Suitable for both home and industrial use.

2. Polycab Superex Electric Wire

Polycab Superex Electric Wire is a superior quality insulated wire with a copper conductor and PVC flexible conduit insulation designed for efficient power transmission. It is known for its robustness and reliability, making it a popular choice for residential wiring. The wire's high-quality insulation protects against electrical faults and ensures a long lifespan, even under continuous use.

Benefits:

- Offers excellent conductivity, ensuring efficient power flow.

- Less heat generation, enhancing safety.

- Cost-effective, providing great value for money.

3. D’Mak KC-Cab Wire

D’Mak KC-Cab Wire is one of the best electric wires for house that features an advanced formulation with a copper core and PVC insulation. It is designed for high performance and safety, suitable for a wide range of electrical applications in homes and businesses. This wire's superior build quality ensures consistent electrical performance and safety, making it a dependable choice for critical applications.

Benefits:

- Ensures 100% conductivity for optimal performance.

- Flame retardant, enhancing safety in case of fire.

- Suitable for voltage grades up to 1100V.

4. Anchor Insulated Copper PVC Cable

Anchor Insulated Copper PVC Cable is an advanced wire with a copper core and PVC insulation. It is designed to withstand high temperatures and provides excellent electrical performance for various applications. Its robust construction and superior insulation make it ideal for environments where high temperatures are common, ensuring durability and safety.

Benefits:

- High-temperature resistance, ensuring durability.

- Low electricity consumption, saving energy.

- Fire-fighting properties, enhancing overall safety.

5. Havells LifeLine Cable

Havells LifeLine Cable is an insulated single-core copper wire with PVC insulation. It is renowned for its quality and safety, making it an excellent choice for residential and commercial wiring. The wire's superior construction ensures long-term reliability, and its protective insulation prevents electrical leaks and short circuits.

Benefits:

- Anti-termite and anti-rodent, ensuring longevity.

- Complies with ROHS, making it environmentally friendly.

- Negligible leakage current, enhancing safety.

6. V-Guard PVC Cable

V-Guard PVC Cable is an insulated PVC cable with a copper conductor suitable for various electrical applications. It is known for its ease of installation and reliable performance in both residential and commercial settings. The flexibility of the electric cable joints and high durability make it a preferred choice for complex wiring setups, ensuring a secure and stable electrical connection.

Benefits:

- Easy to install, making it user-friendly.

- Durable, providing long-lasting performance.

- Reliable, ensuring consistent power supply.

Types of Wire Labeling

Wire labelling provides essential information about the wire’s type, size, capacity, and insulation. These labels help electricians and homeowners select the right wires for their projects and comply with safety regulations. Below are the common types of wire labelling and what they indicate.

| Type | Description |

| Heat-Shrink Sleeves | Printable polyolefin sleeves that shrink to fit tightly around wires. |

| Wrap-Around Labels | Flexible labels that wrap around wires, ideal for curved surfaces. |

| Self-Laminating Labels | Labels with a clear overlay for added protection and legibility. |

| Flags | Small labels for marking small diameter wires, such as fibre optics. |

| Rigid Tags | Durable tags for permanent labelling on larger cables and equipment. |

| Cable Ties with Labels | Cable ties with an integrated labelling area, combining bundling and labelling into one step, which is ideal for organising and identifying multiple cables simultaneously. |

| Clip-on Cable Markers | Pre-printed or blank markers clip onto wires and cables, providing a secure and easily changeable labelling solution for various applications. |

Types of Wire Colours and Meaning

Wire colour coding is essential in electrical systems to ensure safe and proper connections. Different colours indicate specific purposes, helping electricians and users identify wire functions at a glance. Here are the common wire colours and their meanings:

| Colour | Meaning |

| Black | Hot or live wire carries electrical current from the power source to the outlet or device. It's crucial to handle with care as it is always live when the circuit is on. |

| Red | The secondary live wire is used as an additional hot wire in a 220-volt installation or to connect hardwired smoke detectors to the home’s power system. It’s also used in switch legs. |

| White | A neutral wire returns the current to the electrical panel and completes the circuit. It is usually grounded, ensuring safety in the electrical system. |

| Green | Ground wire provides a path for electrical current to ground in case of a fault, enhancing safety by preventing electric shocks and fires. Always connected to the ground. |

| Blue/Yellow Striped | Hotwires for switch legs are used in the context of switch legs, where the blue or yellow wire runs from the switch to the light or other load. They are hot wires when the switch is on. |

Types of Insulation Used in Electric Cables

The insulation material used in electric cables plays a crucial role in protecting the conductor, preventing electrical leakage, and ensuring safe operation. Here are the most common types of insulation used in electric cables:

| Material | Description |

| PVC (Polyvinyl Chloride) | Resistant to flame, moisture, and abrasion. |

| PE (Polyethylene) | Used for high-speed transmission and low capacitance. |

| Neoprene | Resistant to oils and solvents. |

| TPR (Thermoplastic Rubber) | Resistant to heat and harsh weather conditions. |

| FEP (Fluorinated Ethylene Propylene) | High chemical resistance and excellent dielectric properties. |

Safety Tips for Choosing Electrical Wires

Selecting the right wiring type in the home is crucial for safety and efficiency in any electrical installation. Below are some detailed safety tips to help you make the right choice:

1. Check for Certifications

Ensure the electric wire for the house meets national and international safety standards, such as ISI or UL certification. These certifications guarantee that the wires have been rigorously tested for safety, quality, and performance, reducing the risk of electrical hazards and ensuring compliance with regulations. Certified wires provide peace of mind and reliability for both residential and commercial installations.

2. Consider Wire Gauge

The wire gauge determines the wire's ability to carry electrical current. Choosing the correct gauge based on the current load is essential to prevent overheating and potential fires. Heavier loads require thicker wires to handle the increased current safely. Using an undersized wire can lead to excessive heat generation and potentially cause insulation to melt, leading to short circuits or fires.

3. Inspect Insulation Material

The insulation material protects the wire from environmental damage and electrical leakage. Choose durable and flame-retardant materials like PVC or XLPE to ensure long-term safety and performance. Good insulation helps prevent short circuits and ensures that the wire can withstand physical wear, exposure to chemicals, and temperature variations without degrading.

4. Check for Copper Conductors

Copper conductors offer better electrical conductivity and are more durable than aluminium conductors. They ensure efficient power transmission, reduce energy loss, and are less prone to corrosion, making them ideal for long-term use. Copper's superior conductivity and durability make it the preferred choice for most residential and commercial wiring applications.

5. Look for Environmental Resistance

If the wires will be exposed to harsh environmental conditions, select ones designed to withstand moisture, heat, and chemicals. This is particularly important for outdoor or industrial applications where wires may be subject to extreme weather or corrosive substances. Wires with high environmental resistance ensure safe and reliable performance even in challenging conditions, preventing deterioration and electrical failures.

6. Verify Voltage Rating

Ensure the wire's voltage rating matches your electrical system requirements. Using a wire with an appropriate voltage rating prevents insulation breakdown and electrical failures, contributing to overall system safety. A mismatch in voltage rating can lead to insulation damage, electrical arcing, and potential hazards, so it's essential to choose wires designed for the specific voltage levels in your installation.

Understanding the different types of electrical cables and their applications is crucial for creating safe and efficient electrical systems. Whether for residential, commercial, or industrial purposes, choosing the right cable ensures durability, performance, and compliance with safety standards. Always prioritise high-quality materials and professional installation to avoid potential hazards.

How NoBroker Helps with Electrician Services?

NoBroker makes accessing professional electrician services simple and hassle-free, offering reliable solutions for all your electrical needs. The platform connects you with verified and experienced electricians, ensuring safety and high-quality workmanship. Booking services is easy through the NoBroker app or website—just specify your requirements and schedule a time that suits you.

With transparent pricing, there are no hidden costs, giving you complete peace of mind. From fixing faults and installing appliances to complex wiring upgrades, NoBroker covers a wide range of services. Their quick response times and commitment to quality ensure your electrical issues are resolved efficiently. Choose NoBroker for a seamless and dependable experience with your electrician needs.

Find Trusted Electricians Near You – City-wise

Frequently Asked Questions

Ans: Single-core cables have one conductor, which is suitable for simple connections. Multi-core cables have multiple insulated conductors within a single sheath, which is ideal for complex systems requiring multiple connections.

Ans: Select cables based on their application, voltage rating, insulation material, and environmental conditions. Consulting an electrical engineer or referring to standard guidelines ensures safe and efficient usage.

Ans: Ensure cables are of the right type and size for the load, avoid overloading circuits, and keep cables away from water or heat sources. Regular maintenance and proper insulation are essential.

Ans: Power cables are designed to transmit electrical power and are commonly used in residential, commercial, and industrial settings. They are available in various types like low, medium, and high voltage cables.

Ans: Common materials for cable insulation include PVC (polyvinyl chloride), XLPE (cross-linked polyethene), rubber, and Teflon. Each material is chosen based on factors like voltage rating, temperature resistance, and environmental conditions.

Loved what you read? Share it with others!

Most Viewed Articles

Best 10 Switch Brands in India 2026: Top Picks for Smart, Stylish, & Safe Homes

August 25, 2025

98133+ views

Top 10 Wire Companies in India: Founding Year, Valuation, Share Value and More Details in 2026

September 26, 2025

77461+ views

Wire Colour Code in India: Electrical Safety Simplified

January 31, 2025

43876+ views

10 Best Ceiling Fan Brands in India: Features, Price & Warranty in 2026

July 29, 2025

16312+ views

Installing Water Meters in Your Home Society

January 15, 2025

15522+ views

Recent blogs in

V-Guard Vs Polycab Wires: Compare Quality, Safety, Price and Durability

December 18, 2025 by Vivek Mishra

Anchor Vs Havells Wire: Copper Purity, Insulation, Durability & Safety

December 17, 2025 by Ananth

Finolex vs RR Kabel: Safety, Durability, Copper Quality and Price Range

December 17, 2025 by Vivek Mishra

Top 10 Smart Touch Switches Brands in India: Types, Price Range and Warranty

November 18, 2025 by Priyanka Saha

Types of Wiring in a House: Importance, Comparison, Costs and Safety Tips

November 18, 2025 by Priyanka Saha

Full RM + FRM support

Full RM + FRM support

Join the conversation!